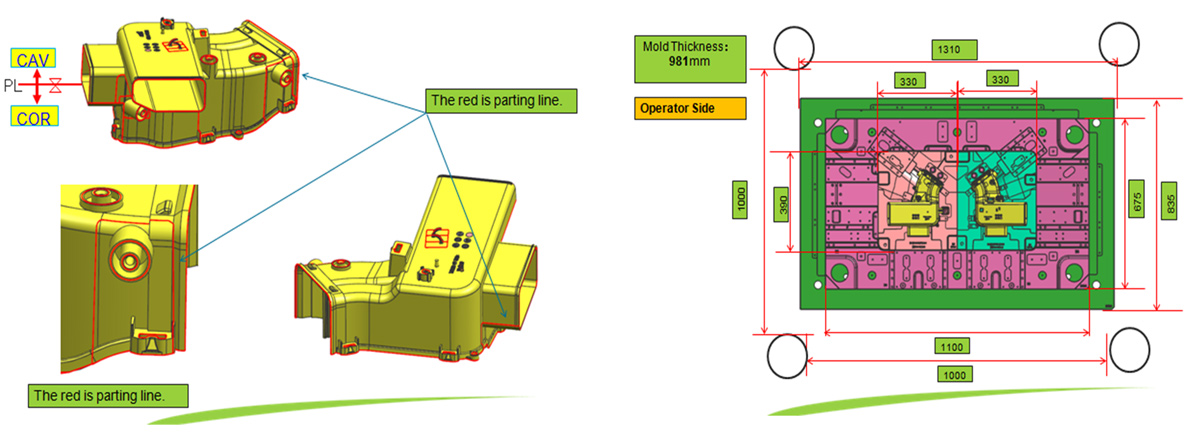

Mold Making

We can provide common design check service at the time of Request-for-Quote (RFQ). We offer engineering advice for material selection and product design in the areas of fitness-for-purpose, tooling feasibility and manufacturability.

This helps to minimize anticipated road blocks in the manufacturing process.

We accept customers'2D/3D CAD drawings from Unigraphics, SolidWorks, ProE and AutoCAD, or in the format of Parasolid X_T or STP, and produce part, product and mold drawings in Unigraphics NX, and share with customers in the format of Parasolid X_T or STP and DWG.

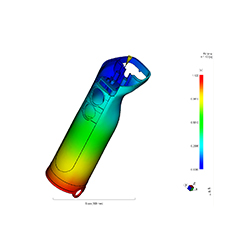

We are equipped with the Moldflow and the Moldex3D tools for mold flow analysis to further eliminate potential issues prior to finalizing part and mold drawings.

We value business partnership with our customers and protect the information and data they provide to us as important as our own. We have tight work practices and procedures to ensure these information and data are properly handled.

Baohong's engineers work with cross functional team from molding shop, tool shop, quality, and engineering. There will be a kickoff meeting to review customer requirements, special characteristics and history record to optimize the mold design.

CAE Moldflow analysis helps to optimize cooling, filling and gate design. High productivity and stable production molds are from our experience and innovative ideas.

Our precision tooling department specializes in manufacturing high quality molds for precision and complex parts in high volume.

All the molds we built are based on customer's requirements and our innovation.

Baohong provides customers with high performance and stable production molds.

We care for all the steps, from design to mass production, we always check how it can be better.

Our molds are high productivity and easy for maintenance, you will find it perfectly achieve your expectation.

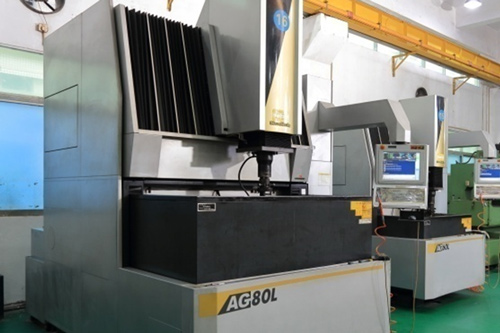

Our tooling facility is equipped with over 90 sets of advanced mold making and inspection machines, including large CNC and double head EDM, and large size coordinate measurement machine.

We're capable of manufacturing large molds for big parts, such as door panel, centrol console, bumper, etc.

The biggest mold we can handle can reach up to 40T in weight.

Baohong Mould utilizes 4 spotting machine to realize efficient tool fitting work .

We are capable of handling tools from 20kg all the way up to 40T.

Baohong's tooling trial department is staffed by experienced molding processing technicians to test each mold prior to shipment.

Our tooling trial department currently have presses ranging from 50T to 800T in house. All the presses are with robot system.